What Are Capping Machines and How Do They Work?In the world of packaging and filling processes, capping is just as essential as the filling itself. Capping machines play a crucial role in sealing containers after they have been filled with products. Whether it’s beverages, cosmetics, pharmaceuticals, or chemicals, capping machines ensure that products are securely sealed to prevent contamination, leakage, or tampering. But what exactly are capping machines, and how do they work? In this article, we’ll explore the types of capping machines, their functionality, and how to choose the best one for your production needs.

What Is a Capping Machine?

A capping machine, often referred to as a capper or capping system, is a piece of industrial packaging machinery designed to apply caps to containers after the filling process. The primary function of a capping machine is to tightly seal containers with caps made from various materials such as plastic, metal, or aluminum. This ensures the safety and integrity of the product, preventing contamination and maintaining freshness.

Capping machines are used across several industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals. They come in various designs and automation levels to accommodate different production scales, from small businesses to large manufacturing facilities.

|

| Fully automatic frequency conversion high speed capping machine |

How Do Capping Machines Work?

The operation of capping machines can vary based on the type of machine and its design. However, the general process involves a few common steps:

1. Cap Placement: The capping machine picks up the cap from a hopper or conveyor system and places it on the container.

2. Sealing: Depending on the type of capping system, the cap is then sealed using different methods such as rotary or press-fit mechanisms. Some machines use pneumatic or mechanical force to tighten the cap to the desired torque.

3. Inspection: After sealing, many capping machines incorporate quality control systems to check if the caps are properly applied and secure.

The specific mechanism of a capping machine varies depending on its automation level, with manual, semi-automatic, and fully automatic machines available.

Types of Capping Machines

Capping machines can be broadly classified into three categories based on their automation level: manual, semi-automatic, and automatic.

1. Manual Capping Machines

Manual capping machines are the simplest and most cost-effective option for small-scale operations. These machines require human intervention to place the cap on the container. Once the cap is in place, the operator manually tightens the cap using a hand tool or lever. Manual capping machines are suitable for low-volume production and are often used by startups or small businesses.

2. Semi-Automatic Capping Machines

Semi-automatic capping machines are more efficient than manual systems. In these machines, the operator places the container under the capping head, and the machine automatically applies the cap and tightens it. Some semi-automatic machines also feature adjustable torque settings to ensure the right tightness for each container type. These machines are ideal for mid-range production volumes and are cost-effective for businesses that require higher output but don’t need fully automated systems.

|

| SFXG-200 Microcomputer controlled semi-automatic capping machine |

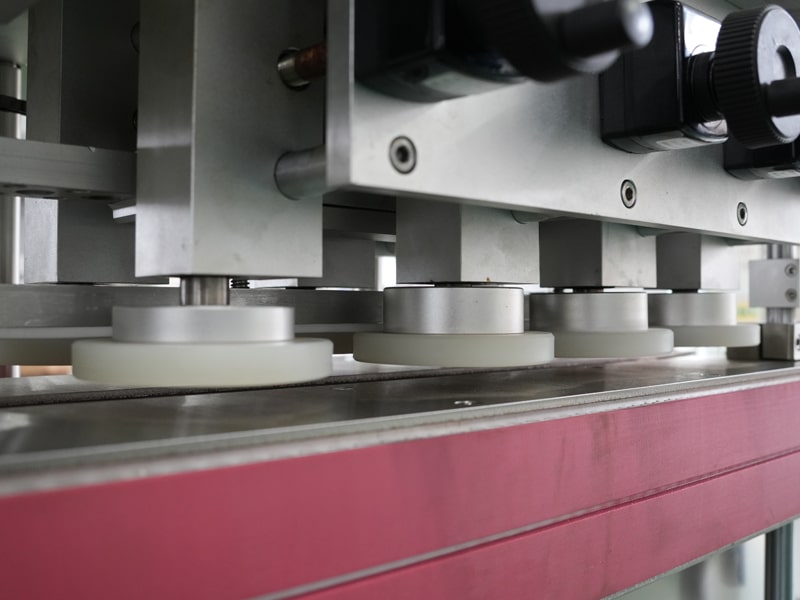

3. Automatic Capping Machines

Automatic capping machines are designed for high-volume production. These machines require minimal human intervention, as they can automatically feed caps, position the containers, and apply the caps. Automatic machines are capable of high-speed operation, often sealing hundreds or even thousands of containers per minute. They are typically integrated into larger production lines, working seamlessly with filling and labeling systems. Automatic capping machines are ideal for large manufacturers that require maximum efficiency and speed.

Types of Capping Methods

There are several methods used by capping machines to seal containers. These methods vary depending on the type of cap used and the sealing requirements of the product. Some common capping methods include:

1. Screw Capping: This is the most common method for sealing containers, especially in the food and beverage industry. A screw capping machine uses rotating heads to twist the cap onto the bottle, creating a tight seal.

2. Press Fit Capping: Press-fit capping machines apply caps to containers using pressure, without twisting the cap. This method is often used for snap-on caps and other non-threaded closures.

3. ROPP (Roll-On Pilfer-Proof) Capping: ROPP capping is a special technique used to apply tamper-evident aluminum caps, commonly seen on wine and beverage bottles. The machine uses rollers to crimp the cap tightly around the bottle neck, ensuring that it cannot be removed without evidence of tampering.

4. Push-On Capping: Push-on capping involves applying a cap that snaps securely onto the container by simply pressing it in place. This method is commonly used for bottles that require a tight fit, such as certain beverage or pharmaceutical containers.

Choosing the Right Capping Machine

When selecting a capping machine for your business, there are several factors to consider to ensure the machine fits your production needs:

1. Production Volume: If you’re running a small-scale operation, a manual or semi-automatic capping machine may be sufficient. However, for high-volume production, an automatic capping machine is necessary to meet your demands efficiently.

2. Cap Type and Container Size: Consider the types of caps and containers you will be working with. Some capping machines are designed to handle specific cap types, such as screw caps, press-fit caps, or ROPP caps. Additionally, the machine should be adjustable to accommodate various container sizes.

3. Automation Level: Automation can significantly improve production efficiency. Fully automated capping machines can seamlessly integrate into your production line, reducing labor costs and increasing throughput.

4. Machine Compatibility: Ensure the capping machine is compatible with other equipment in your production line, such as fillers, labelers, and conveyors. This will streamline your entire packaging process.

5. Budget: The cost of capping machines can vary widely based on features, automation level, and production capabilities. It’s essential to find a machine that offers the best value for your specific needs.

Benefits of Capping Machines

Using a capping machine offers numerous advantages, including:

Increased Efficiency: Capping machines can significantly reduce the time required to seal containers compared to manual methods, boosting overall production efficiency.

Consistent Sealing Quality: Capping machines ensure consistent and accurate application of caps, reducing the risk of human error.

Reduced Labor Costs: By automating the capping process, businesses can minimize the need for manual labor, lowering operational costs.

Enhanced Product Safety: A securely sealed container ensures that the product remains safe from contamination or leakage, extending its shelf life and maintaining quality.

Conclusion

Capping machines are an essential part of modern packaging lines, ensuring that products are sealed securely and efficiently. Whether you are a small business or a large manufacturer, selecting the right capping machine can improve production speed, reduce costs, and maintain high-quality standards. As packaging machinery manufacturers continue to innovate, there are more options than ever to meet the diverse needs of the packaging industry.

If you are looking for reliable capping machines, SFXB Packaging Machinery(https://www.xuebapack.com) offers a range of advanced solutions for various industries, ensuring your packaging process is streamlined and efficient.

| References: | |

| 1. | ”Hand-Held Capping Machines market Analysis- Industry Size, Share, Research Report, Insights, Covid-19 Impact, Statistics, Trends, Growth and Forecast 2025-2034” –Retrieved from: MarkWide Research |

| 2. | “12+ considerations for selecting your next capping machine” –Retrieved from: Packaging World |

| 3. | 《ROPP Capping Technology for Tamper-Evident Packaging》–Retrieved from:《Food Packaging Journal》 |

| 4. | 《《The Essential Guide to Automatic Capping Machines in Manufacturing》》–Retrieved from: ResearchGate |

Comments